Stator Windings Can Best Be Described as _____

The vibration amplitudes are proportional to the square of the current and the frequency is twice the electrical line frequency. Due to the complicated winding structure and the steel core the attenuation and distortion of a pulse transmitted through the winding are complicated and frequency-dependent.

Electric Generator Stator Windings Britannica

Windings is 100 focused on providing custom electric motor solutions that are optimized tested and manufactured to client-specific.

. Windings can wind stator coils and build custom stator assemblies from 05 to 30 762 mm in diameter and up to 2000 pounds 892 kg. The notation Nasi in Figure 42-1 indicates the number of conductors in the ith slot of the a stator winding. The stator windings are formed of slot segments that are located in the slots and end loop segments that connect two adjacent slot segments of each phase and are formed in a predetermined.

In addition Windings offers precision machining and insertion of winding assemblies into housings. Stator winding is made up of former wound coils of high conductivity copper of diamond shape. Stator windings The maximum value of flux density in the air gap is limited by magnetic saturation in the stator and rotor iron and is typically about one tesla weber per square metre.

ITAR and RoHS compliant and lead free. Go to Next Almost Good Answer. The stator windings for all of the phases share the same core and the phase belts overlap meaning that slots will contain wires from different phases.

Test can be utilized to determine the optimal sensor locations and thus maximize the benefit of monitoring stator endwinding vibration. Design of stator winding. Stator end-windings are excited by electromagnetic forces during the operation.

With _any_ transformer or inductor when you apply voltage to a coil you will get a changing magnetic field which will induce back emf in that coil. Bump testing analyzes the natural response of stator end-windings upon excitation from a mechanical impulse. You use the megger to check the the stator winding to to ground or the metal frame of the generator for leakage or resistance you would use a kelvin bridge to check the windings of the stator.

The name asynchronous motor is also applicable for. These emfs must have same wave shape and be displaced by 120 0 to each other. Register to Reply Score 1 for Good Answer.

The degradation of stator winding insulation can be described in general terms by using two curves to demonstrate how stress and strength change over time 3. Other articles where stator winding is discussed. The effective or root-mean-square rms voltage induced in one turn of a.

A coil winding machine comprising a plurality of winding heads disposed in spaced relationship with one another a work holder having means for supporting a workpiece in operative relationship with the winding heads and control means for oscillatingly moving the workpiece back and forth between selected ones of the winding heads during the winding operation. A relatively common major repair encountered by generator owneroperators is replacement of the stator winding. Capabilities include design prototyping and pre-production run to volume production.

On end-windings with loose supports larger vibration amplitudes can be measured at partial load than at full load. 421 Discrete Windings Figure 42-1 illustrates the stator of a machine in which the stator windings are located in a set of slots also shown is a path of integration this will be discussed later in the section. Discharge can be useful to diagnose the condition of the stator winding insulation and identify many problems that could lead to insulation failure.

The effective or root-mean-square rms voltage induced in one turn of a stator coil in a 2-pole 60-hertz generator is about 170 volts for each metre squared of area encompassed by the turn. The alternating current AC makes the. The induction motor used for this example is a three-phase two-pole machine and it can be described exactly by the phasor diagram where 60 defines the pole pitch in the stator.

This paper describes common problems caused by endwinding vibration the offline impact or bump test and the online monitoring system using practical case studies for each. The maximum value of flux density in the air gap is limited by magnetic saturation in the stator and rotor iron and is typically about one tesla weber per square metre. There are two general methods for designingconstructing stator windings Jamie Clark of AGT Services Inc told attendees at the 501F Users Groups 2020 Conference and Vendor Fair last February at the Hilton West Palm Beach Fla.

When the power supply is given to the stator an AC flows through the stator windings to create an electromagnetic field across the bars of the rotor. Ump Test of Generator Stator End Windings. A generator stator winding consists of a number of stator bars and overhang connections.

Many years of experience however has shown these quantities by themselves cannot predict the remaining life of a winding. However asset managers would. Stator is an immobile part of the electric motor which includes several windings.

Therefore the selection of the suitable winding technology and a proper design are mandatory to fulfill the challenging requirements. Because of voltage producing them with subindex n standing for negative this the negative 5th harmonic of the stator voltage vector is sequence considered as the best candidate to use as a high-frequency excitation voltage when detecting the asymmetries in the stator isqds Ip hejhωe tϕp h In hejhωe tϕn h windings. Once an alternating current is applied to it then its polarity will be changed all the time.

In its simplest form the three-phase random wound stator winding process consists of removing an existing winding from a stator and replacing it with a winding that duplicates the original winding performance characteristics. The conductors the bars and the complete stator end windings can be considered as a mechanical. One of the tests to assess the condition of generator stator end windings is the performance of a bump test.

AbstractThe stator winding is known to be a key factor to enhance the performance of electrical machines in terms of ef-ficiency lifetime volume and consequently the costs. These windings must be properly arranged such that the induced emf in all the phases of the coils must have the same magnitude and frequency. Single or double layer.

Helical windings are available. Windings can be used in automotive commercial industrial medical military naval and aerospace applications. The stress curve shows the combined loading on the winding insulation arising from its operation including irregular conditions such as transients.

Manufacturer of standard and custom stator windings. The only challenge here is that these angles of separation between each stator only work in. Usually stator windings is 3phase windings similar or same as with synchronous motors but air gap is smaller.

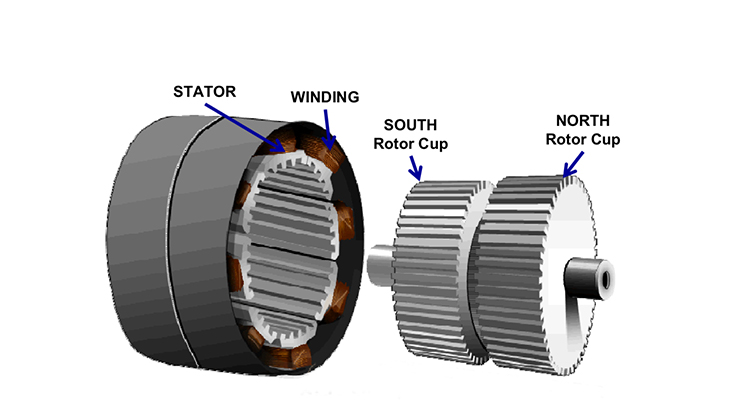

Stepper Motors Permanent Magnet Variable Reluctance And Hybrid

Comments

Post a Comment